What is ESD Access Control System?

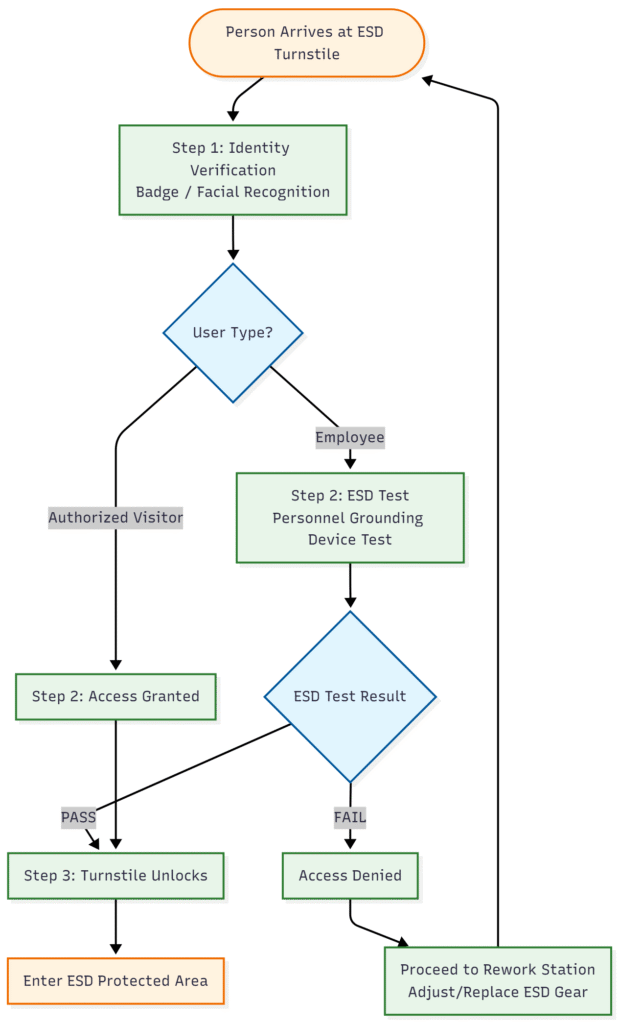

ESD Access Control System is a comprehensive security measure that integrates ESD testing, ESD turnstile and access control into a cohesive solution for ESD protected Area. This system is designed to grant entry privileges solely to employees who have passed their personal grounding device tests.

ESD Access Control System Overview Video

What is an ESD turnstile?

An ESD turnstile is a physical barrier integrated with ESD testing system designed to test the resistance of personnel grounding devices, ensuring that individuals entering an ESD protected area (EPA) are compliant with ESD safety standards. Furthermore, ESD turnstiles can incorporate access control mechanisms to strictly regulate entry into the area, thereby enhancing the overall ESD protection by preventing unauthorized access and ensuring that only personnel with proper grounding are allowed entry.

How much does ESD turnstile gate system cost?

As a general guideline, the typical cost range for an ESD (Electrostatic Discharge) turnstile gate system can be anywhere from $2,000 to $8,000. The cost of can vary depending on several factors, such as the specific features, add-ons, and vendor. Welcome to contact us for a quick quote.

Designing an Effective ESD Protected Area (EPA) with Turnstiles as the Entry Point

Designing an effective EPA entry point is not just about installing a turnstile; it involves integrating acess control, ESD compliance verification, flow management, and identity authentication into a seamless and efficient system.

1. Core Objectives and Design Principles

- 100% Compliant Access: Ensure every individual entering the EPA has completed necessary ESD protective measures (donning ESD-safe garments, footwear, wrist straps, etc., and passing the test).

- High-Efficiency Passage: Quickly manage pedestrian flow during peak hours, such as shift changes, to avoid congestion.

- Traceability: Record who entered the EPA and when, meeting the management requirements of high-end manufacturing and laboratories.

- Enforcement: Use physical barriers (turnstiles) and logical checks (testing system) to eliminate the possibility of “bypassing” procedures.

- Standards Compliance: The design must adhere to international ESD protection standards such as ANSI/ESD S20.20 or IEC 61340-5-1.

2. Three Types of ESD Turnstiles and Selection Criteria

The core differences between these three turnstiles lie in their blocking method, passage speed, and security level.

| Type | ESD Tripod Turnstile | ESD Flap Barrier | ESD Swing Barrier |

| Image |  |  |  |

| Blocking Method | Rotation of 3 metal bars | Acrylic flaps extend from and retract into the chassis | Two glass doors that swing open |

| Passageway Width | 600mm | 600mm or 900mm | 600mm to 900mm |

| Passage Speed | Slow (35-30 persons/minute) | Fast (40-45 persons/minute) | Fast (35-40 persons/minute) |

| Anti-Tailgating | Excellent, allows only one person at a time | Good, relies on sensor logic | Poor, requires more sensors and algorithms |

| Cost | Lowest | Medium | Medium |

| Ideal Use Cases | – Areas with extremely high-security requirements – Stable, non-extreme peak traffic flow – Budget-conscious but requiring high enforcement | – High-traffic entrances requiring efficiency – Scenarios balancing security and speed – Modern, tech-oriented environments | – Pursuing ultimate passage experience and aesthetics – High traffic flow, possibly carrying small items – High integration with other access control systems |

3. Entry Layout and Personnel/Material Flow Planning

The core of the layout is to create a “funnel” process that guides personnel through all necessary steps.

1. Functional Zoning:

- Preparation Area: Located outside the entry. Equip with dispensers for shoe covers, ESD garments, and informational posters.

- Pre-check/Authentication Area: Personnel perform identity verification here (card, face, etc.).

- ESD Testing Area(Turnstile Passage): Core Zone. Place ESD testers (comprehensive human body resistance testers). Personnel stand on the footplates and may be required to touch a hand test point. The tester is interlocked with the turnstile.

- EPA Internal Buffer Zone: A small area inside the turnstiles to prevent congestion right at the gateway.

2. Passage Number Calculation:

- Key Parameters:

N: Number of people needing entry per minute during peak hours.T: Average time (seconds) for one person to complete verification, testing, and passing through the turnstile.E: Theoretical throughput per passage (persons/minute) =60 / T.

- Calculation Formula:

- Required Number of Passages M = N / E

- Example:

- Peak hour requires 60 persons/minute entry.

- Using ESD Flap Barriers, average time per person is 3 seconds (including walking, testing, turnstile reaction), so

E = 60 / 3 = 20 persons/minute. M = 60 / 20 = 3. Therefore, at least 3 passages are needed.

3. Material and Personnel Flow:

- Personnel Flow:

- Material Flow:

- The EPA entrance should NOT be the main pathway for materials. Materials should enter through separate, grounded entrances via ESD-safe carts or conveyors.

- If personnel must carry small components, provide an ESD-safe transfer bench at the entrance. Personnel place items on the bench, pass the test themselves, and then retrieve the items from the inside of the bench within the EPA.

4. Personnel Authentication Methods

The choice of authentication method depends on security level, budget, and usability requirements.

| Method | Card/Badge | Face Recognition | QR Code/barcode |

| Image |  |  |  |

| Pros | – Mature technology, low cost – Simple deployment – Card can integrate access control, time attendance | – Highest convenience, contactless – Prevents buddy punching – Highest security and traceability | – Less prone to loss – Can generate temporary visitor QR codes – Easy integration with visitor management systems |

| Cons | – Can be forgotten, lost, or damaged – Risk of card lending/sharing | – Highest initial investment – Potential privacy concerns – Affected by lighting, obstructions | – Requires taking out phone, slightly more steps – Relies on network connectivity – Screen glare may affect scanning |

5. Complete System Integration and Workflow

An ideal, highly automated EPA entry system workflow is as follows:

- Employee Approaches: Employee approaches the EPA entrance.

- Identity Authentication:

- Option A (Face Recognition): Employee looks at the camera; the system instantly verifies identity.

- Option B (Card/QR Code): Employee swipes a card or presents a mobile QR code.

- System Response: Upon successful verification, the system illuminates the “Please Test” indicator for that passage, and the ESD tester prepares.

- ESD Compliance Test: Employee stands on the tester’s footplates and touches the hand test point (if required). The tester measures the body-to-ground resistance.

- Logic Decision & Turnstile Control:

- Test Pass: Resistance is within the safe range (e.g., 750kΩ ~ 35MΩ). The tester sends a “Pass” signal to the turnstile, which opens (e.g., flaps retract), a green light illuminates, and passage is granted.

- Test Fail: Resistance is out of range. The turnstile remains locked, a red light illuminates, the screen displays the failure reason (e.g., “Shoe Covers Not Worn”, “Wrist Strap Not Connected”), and directs the employee to the exception handling area.

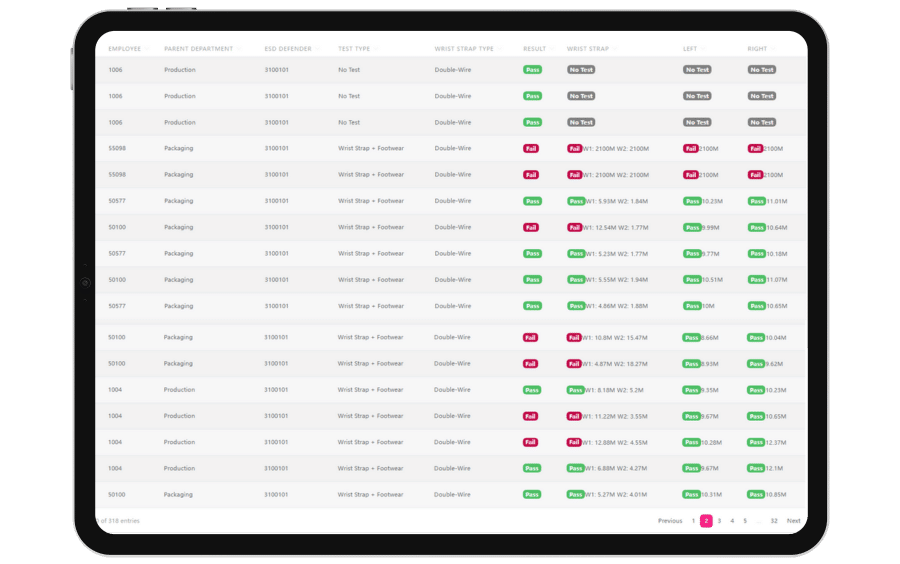

- Recording & Traceability: Regardless of pass or fail, the system logs an entry:

[Timestamp][Employee ID][Passage Number][Test Result]. This data is usable for audits and issue analysis.

Summary: Design Steps Checklist

- Requirements Analysis: Determine peak hour traffic flow, total number of employees, security level requirements, and budget.

- Turnstile Selection: Based on Step 1, make a preliminary choice among Tripod, Flap, and Swing types.

- Passage Quantity Calculation: Based on traffic flow and turnstile efficiency, determine the number of passages and plan for a “Visitor Passage”.

- Authentication Method Selection: Decide on the primary and backup methods among Card, QR Code, and Face Recognition.

- Layout Design: Create a floor plan defining the spatial relationship between the pre-check, testing, turnstile, and buffer zones, and map the personnel and material flows.

- System Integrator Selection: Choose an experienced supplier to ensure seamless integration between ESD testers, turnstiles, access controllers, and management software.

- Develop SOPs: Write Standard Operating Procedures and train employees and security personnel on correct usage and exception handling.

By following this systematic planning and design approach, you can construct an EPA entrance that is not only standards-compliant but also efficient, intelligent, and reliable, providing a solid first line of defense for your sensitive electronic products and equipment.

Why EPA requires ESD Access Control System rather than a single ESD Tester?

EPA is a designated workspace or environment designed to minimize the risk of electrostatic discharge-related damage to sensitive electronic components and devices.

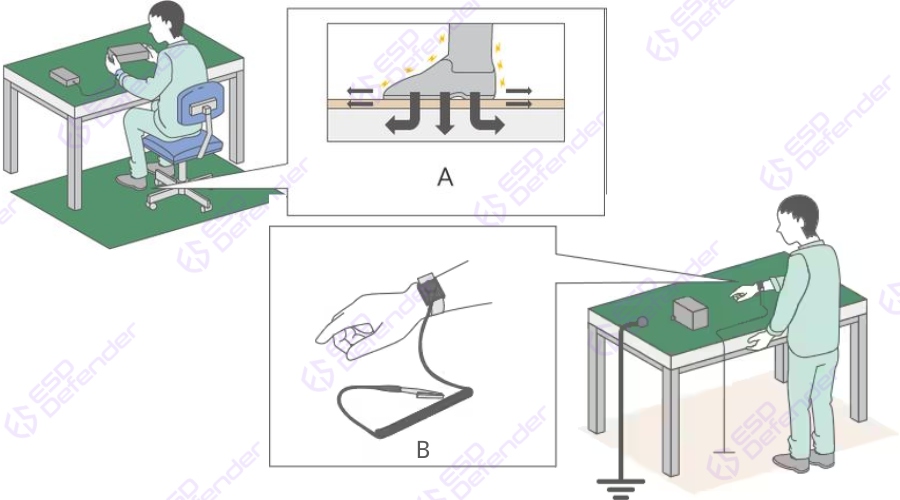

Grounding is the simplest and most effective method for ESD control of conductive materials, including personnel grounding. Therefore, employees must wear ESD wrist straps, ESD grounders, or ESD footwear in EPA. However, the effective functioning of these devices cannot be determined by visual inspection alone.

Limitations of using ESD tester without access control system

As a result, we require an ESD tester, which is a testing device used to evaluate the effectiveness of employee grounding equipment. However, using ESD tester only has the following limitations:

- Rely on manned monitoring-Employees may bypass the testing when not under direct supervision.

- Require for manual data recording- This may lead to potential for human error and inaccuracies

- Paper-based data storage-Maintaining paper-based test records impedes long-term tracking and corrective actions.

- Inability to prevent unauthorized personnel from entering the protected area.

Benefits of ESD access control system

The limitations of the traditional ESD tester highlight the need for a more advanced solution like the ESD Access Control System, which offers a range of key benefits to enhance EPA management:

- Automated Testing and Monitoring: The ESD Access Control System can automatically detect the ESD protective equipment worn by employees, eliminating the need for manual supervision and improving the continuity and reliability of the testing process.

- Real-Time Data Recording: The system can record each employee’s test data in real-time, avoiding the potential for errors associated with manual record-keeping.

- Digital Data Storage: The system utilizes an electronic database to store the test records, significantly improving the efficiency and security of data management.

- Historical Data Tracking: The system can maintain long-term test records, enabling analysis of trends and the implementation of timely corrective measures.

- Automatic Alerts: The system can immediately trigger alerts upon detecting any abnormal conditions, ensuring the safety of the EPA environment.

- Access Control: Integrated with ESD turnstile or electornic door lock, it can restrict unauthorized personnel from entering the EPA area, further strengthening the control of electrostatic discharge protection.

- Data Analysis: The system can generate various statistical reports, helping management personnel better understand the operational status of the EPA.

- Scalability: The ESD Access Control System has good scalability, allowing for flexible upgrades and adjustments based on evolving requirements.

- Improved Efficiency: The automated testing and monitoring significantly reduce the burden of manual management, thereby enhancing the overall operational efficiency.

- Regulatory Compliance: The use of this system can help organizations meet the relevant electrostatic discharge protection regulations, reducing compliance risks.

What is the principle of ESD control?

Understanding the generation of static electricity paves the way to grasping the principles of ESD control:

- Grounding of All Conductors, Including Personnel

- Removal of Unnecessary Non-Conductive Materials (Insulators)

- Using ESD Protective Packaging

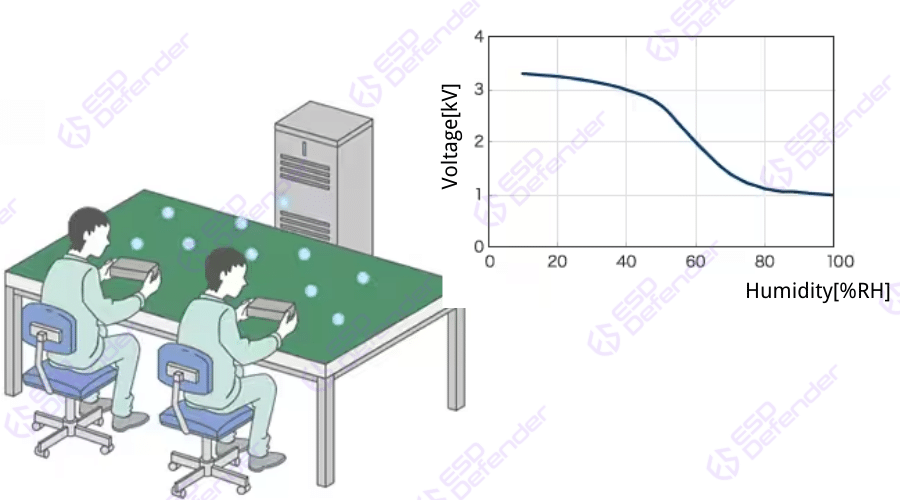

- Humidity Control

Grounding of All Conductors, Including Personnel

Grounding prevents the accumulation of static charges on a conductor by providing a path for the charges to flow to the ground, thus neutralizing potential hazards.

- Ensure all personnel working in the ESD-sensitive area wear static-dissipative wrist straps that are properly grounded. ( Remember to utilize an ESD combo tester to assess the performance of both the wrist strap and footwear. )

- Require personnel to wear static-dissipative footwear or use conductive flooring to maintain a ground path.

- Ground all conductive surfaces, equipment, and fixtures using dedicated grounding systems.

Removal of Unnecessary Non-Conductive Materials (Insulators)

Insulating materials, or non-conductors, are prone to generating and retaining static charges. Without proper control, these materials can pose significant ESD risks.

- Replace non-conductive materials with static-dissipative or conductive alternatives, such as using ESD-safe tabletops, flooring, and shelving. Don’t forget to use surface resistivity meter to measure surface resistance and ensure materials meet ESD standards.

- Utilize ionizers to neutralize static charges on insulating surfaces and materials that can not be replaced.

- Maintain a minimum clearance between insulating materials and ESD-sensitive devices to minimize the risk of discharge.

Using ESD Protective Packaging

- Package ESD-sensitive devices in static-shielding bags, conductive containers, or other ESD-safe packaging before transportation and storage.

- Ensure the packaging provides a Faraday cage effect to distribute external static charges evenly on the outer surface, protecting the contents.

Humidity Control

The diagram below shows the natural discharge of static electricity as humidity increases. It is generally considered that when the relative humidity exceeds 65%, it is difficult for static electricity to be generated, and even if it is, it can be naturally dissipated. Therefore, this value is used as the benchmark for humidity management.

Why is ESD control important?

ESD (Electrostatic Discharge) control is important for several reasons:

- Preventing Damage to Electronic Components: Electronic components, particularly sensitive semiconductor devices, can be easily damaged by static electricity. ESD can cause immediate failure or latent defects that lead to premature failure of the component. Proper ESD control measures help protect these sensitive components.

- Ensuring Product Reliability: Uncontrolled ESD can lead to intermittent failures or gradual degradation of electronic products over time. Implementing ESD control measures helps maintain the long-term reliability and performance of electronic devices.

- Compliance with Industry Standards: Many industries, such as electronics manufacturing, have established ESD control standards and guidelines that must be followed to ensure product quality and safety. Adhering to these standards is often a legal requirement.

- Reducing Warranty and Repair Costs: ESD-related failures can lead to increased warranty claims and product returns, which can be costly for manufacturers. Effective ESD control helps minimize these expenses.

- Protecting Personnel: Static electricity can also pose a safety risk to personnel, as it can cause shocks or even ignite flammable materials. ESD control measures help protect workers from these hazards.

Overall, ESD control is crucial for maintaining the integrity and reliability of electronic products, ensuring compliance with industry regulations, and protecting both equipment and personnel from the harmful effects of static electricity.

Major Sources of Electrostatic Discharge in the Electronics Industry

The electronics industry is a high-risk area for electrostatic discharge (ESD). During the various manufacturing and assembly processes of electronic devices, such as testing, soldering, heating, drying, cleaning, inspection, handling, packaging, and transportation, the components inevitably experience collisions and frictional contact, which can generate high electrostatic potentials. Furthermore, if the operator is charged for any reason and does not implement reliable anti-static measures, the electrostatic potential of the human body can reach as high as 1.5-35 kV, which can also lead to damage or soft breakdown of the electronic devices.

In fact, the human body and the electronic devices themselves are significant sources of static electricity. Charged human bodies and charged devices both constitute ESD sources that pose a threat to the electronic components. There are also other static electricity sources in the environment surrounding the electronic devices, such as work-related static and packaging materials.

| Workbench Surfaces | – Waxed, painted, or lacquered surfaces – Regular vinyl materials – Various plastics |

| Flooring | – Sealed concrete – Waxed or painted wood flooring – Regular vinyl tiles or sheets |

| Clothing | – General clean room garments – Typical synthetic fiber work clothes – Regular shoes – Dry cotton (below 30% RH) |

| Chairs | – Vinyl chairs – Fiberglass chairs – Painted wooden chairs |

| Packaging and Handling | – General plastics (bags, cases, envelopes) – Regular bubble wrap, foam materials – General plastic trays, totes, transport boxes, vials – Component storage containers |

| Assembly, Cleaning, Testing, Repair Areas | – Spray cleaning equipment – Regular desoldering tools – Ungrounded soldering irons – Brushes (synthetic bristles) – Liquid or evaporative cleaning/drying – Low-temperature spray guns or hot air guns – Sandblasting – Electrostatic copying |

| Chip Carriers | – Chip trays and racks – Magazines – Tools |

| Logistics Equipment | – Storage cabinets – Handling carts |

| High Voltage Equipment or Sources | – Various metal parts, components, and equipment that can induce static electricity |

How to use ESD check station?

ESD check station, also called ESD test station, is a specialized workstation designed to measure and control electrostatic discharge (ESD) in electronic manufacturing and assembly environments. To use an ESD check station, begin by ensuring that all personnel are wearing appropriate ESD protection gear, such as wrist straps or ankle straps, which are grounded to prevent static buildup.

Additionally, it is essential to utilize a surface resistance meter to measure the resistance of various materials that will be used in ESD-sensitive work areas. This measurement helps ensure that the surfaces and tools maintain proper conductivity, further reducing the risk of ESD and protecting sensitive electronic components.