Was bedeutet IEC 61340-5-1?

IEC 61340-5-1 ist eine internationale Norm, die von der Internationalen Elektrotechnischen Kommission (IEC), die sich auf den Schutz elektronischer Geräte vor elektrostatischen Phänomenen bezieht. Sie umreißt die allgemeinen Anforderungen, die notwendig sind, um die mit elektrostatischen Entladungen (ESD) verbundenen Risiken, die empfindliche elektronische Bauteile und Geräte beschädigen können, zu mindern.

Was ist die neueste Version der IEC 61340 5-1?

Die neueste Fassung der IEC 61340-5-1 ist IEC 61340-5-1:2024die am 21. Mai 2024 veröffentlicht wurde. Diese Ausgabe ist die dritte Version der Norm und ersetzt die vorherige Version von 2016.

Ist IEC 61340 5-1 oder ANSI ESD S20.20?

Die Norm IEC 61340-5-1, die von der Internationalen Elektrotechnischen Kommission (IEC) veröffentlicht wurde, ist in internationalen Umgebungen anwendbar, insbesondere in Europa und anderen Regionen, die sich an die IEC-Normen halten. Sie umreißt die Anforderungen an Programme zur Kontrolle elektrostatischer Aufladungen, einschließlich Arbeitsplatzgestaltung, Personalschulung, Erdungssysteme und Ionisierungsgeräte.

Andererseits, ANSI/ESD S20.20 ist eine nationale Norm, die von der ESD Association in den Vereinigten Staaten entwickelt wurde. Sie findet in der Elektronikindustrie in Nordamerika und weltweit breite Anwendung, insbesondere bei Unternehmen, die Waren für den US-Markt liefern.

Herausfinden Hauptunterschiede zwischen IEC 61340 5-1 und ANSI ESD S20.20.

Welche Branchen müssen die IEC 61340-5-1 umsetzen?

Die Norm IEC 61340-5-1 gilt in erster Linie für Industrien, die einen Schutz vor elektrostatischen Entladungen (ESD) bei der Handhabung und Herstellung von ESD-empfindliche elektronische GeräteIm Einzelnen umfasst es die folgenden Sektoren:

- Elektronik- und Elektroindustrie: Umfasst die Produktion von Halbleitern und elektronischen Bauteilen

- Informationstechnologie und Kommunikation: Beinhaltet Computerhardware und Kommunikationsgeräte

- Automobilindustrie: Enthält viele elektronische Teile, die aus Sicherheitsgründen eine statische Kontrolle erfordern.

- Luft- und Raumfahrt: Erfordert strenges statisches Management aufgrund hoher Zuverlässigkeitsanforderungen.

- Herstellung von Unterhaltungselektronik: Umfasst Produkte wie Fernsehgeräte und Smartphones

- Herstellung medizinischer Geräte: Geräte sind ESD-empfindlich, so dass ein robuster Schutz während der Produktion unerlässlich ist.

Welches sind die wichtigsten Anforderungen, die in der IEC 61340-5-1 beschrieben sind?

IEC 61340-5-1 umreißt die wichtigsten Anforderungen in zwei Hauptbereichen: administrativ und technisch.

Die administrativen Anforderungen umfassen:

- Erstellung eines ESD-Kontrollprogrammplans: Unternehmen müssen ein umfassendes ESD-Kontrollprogramm entwickeln, um einen wirksamen Schutz von elektronischen Geräten zu gewährleisten.

- Ausbildung und Bewusstseinsverbesserung: Regelmäßige Schulungen für Mitarbeiter sind notwendig, um das Bewusstsein für den ESD-Schutz zu schärfen und die Fähigkeiten zu verbessern.

- Produktqualifizierung: Durchführung von Produktqualifizierungen, um sicherzustellen, dass elektronische Produkte eine angemessene Immunität gegen elektrostatische Entladungen (ESD) aufweisen.

- Aufstellung eines Plans zur Überprüfung der Einhaltung der Vorschriften: Es sollte ein Plan zur Überprüfung der Einhaltung der Vorschriften entwickelt werden, um die Wirksamkeit und Umsetzung der ESD-Kontrollmaßnahmen zu validieren.

Die technischen Anforderungen umfassen:

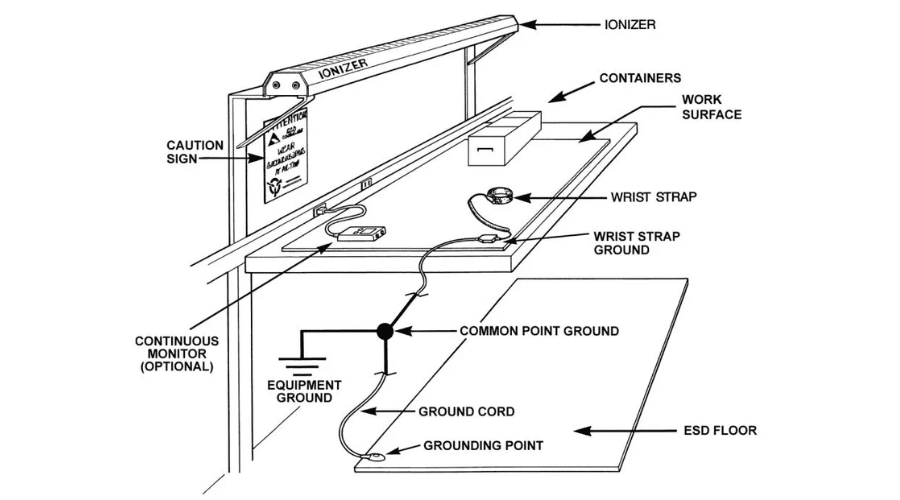

- Erdung/Potentialausgleichssysteme: Es müssen wirksame Erdungs- und Potentialausgleichssysteme eingerichtet werden, um die Ansammlung statischer Ladungen zu verhindern.

- Erdung des Personals: Um den Aufbau statischer Elektrizität während der Arbeit zu minimieren, sollten geeignete Techniken zur statischen Erdung des Personals angewendet werden.

- Definition von Elektrostatisch geschützte Bereiche (EPAs): Legen Sie die Grenzen der elektrostatisch geschützten Bereiche klar fest, markieren Sie die Geräte und Werkzeuge mit den richtigen ESD-Symbole.

- Verpackung: Um elektronische Produkte während des Transports und der Lagerung vor ESD zu schützen, sollte geeignetes antistatisches Verpackungsmaterial verwendet werden.

- Identifizierung: Eine eindeutige Kennzeichnung der statischen Schutzausrüstung und der Bereiche ist notwendig, um die Sichtbarkeit und die Einhaltung der Vorschriften zu verbessern.

Was entspricht der EN 61340-5-1?

Zu den wichtigsten Aspekten, die der EN 61340-5-1 entsprechen, gehören: ESD-Schutzbereich (EPA), persönliche Erdung, ESD-Kontrollprodukte, Schulung und Sensibilisierung, Überwachung und Wartung, Dokumentation und Einhaltung, Umweltkontrollen und Handhabungsverfahren.