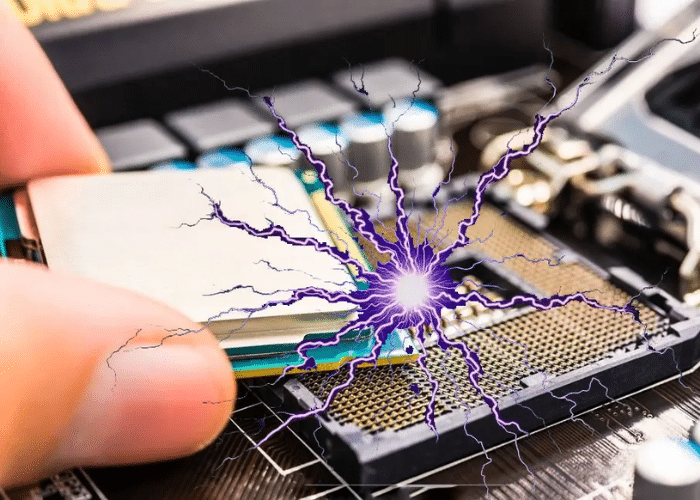

That sudden shock you feel when touching a doorknob in winter? That’s electrostatic discharge (ESD) – the same invisible threat that damages electronics. When walking, sitting, touching objects, or working while ungrounded, the human body accumulates electrical charge. This trapped charge poses serious risks: touching ESD sensitive items like semiconductors can cause ESD damage, while contact with production or testing equipment may trigger malfunctions. Though highly destructive to electronics, the most challenging aspect is that low-level static charges are often imperceptible – making them hard to detect. The chart below shows how different levels of body charge correlate with shock intensity.

The chart below shows how different levels of body charge correlate with shock intensity.

| Voltage (kV) | Sensation Perceived |

| 1.0 | Undetectable |

| 2.0 | Tingling in fingers (no pain) |

| 3.0 | Sharp, pinprick-like pain |

| 5.0 | Pain in the palm and forearm |

| 6.0 | Strong finger pain; heaviness in upper arm |

| 7.0 | Intense pain + numbness in fingers/palm |

| 8.0 | Numbness in palm and forearm |

| 9.0 | Sharp wrist pain; numbness in hand |

| 10.0 | Pain throughout hand; electric current sensation |

| 11.0 | Strong finger numbness; intense shock throughout hand |

| 12.0 | Heavy blow sensation throughout hand |

The chart shows that 3 kV causes prickling pain. Blue-white sparks appear at 10 kV+. Charges below 2 kV often go undetected. However, in manufacturing, static under 1 kV can cause critical damage: it may unknowingly destroy semiconductors or disrupt equipment.

What is ESD damage?

ESD damage is the destruction or degradation of electronic components caused by sudden static electricity discharges—even ones too small to see or feel.

Types of ESD Damage

· Catastrophic failure

Catastrophic failure occurs when ESD instantly destroys a component, rendering it completely non-functional – like a microprocessor burning out from a single static shock.

· Latent defects

Latent defects are more insidious, where ESD weakens a component but it continues working temporarily, only to fail prematurely weeks or months later.

· Upset failures

Upset failures involve temporary malfunctions like data corruption or system glitches without permanent damage, often seen in memory chips or sensors that give erratic readings after an ESD event.

ESD-related damage across various industries

Electrostatic discharge (ESD) damage now affect all industries, particularly those in electrical and electronic equipment manufacturing.

Semiconductor, Electronics, & LCD Industries:

- Packaging/Internal Circuits: When static electricity flows through packaging or internal circuits, it can cause circuit damage, altered characteristics, and reduced yield.

- Glass Panels: Can cause damage to LCD glass panels, transistor failure, and similar issues.

Electronics Manufacturing Industry:

- Packaging/Assembly: If operators or components themselves are charged, unexpected discharge can cause complete or partial burnout of components.

- Packaging Materials: Static charge attracts dust and debris, increasing the risk of foreign object contamination during packaging.

Chemical Industry:

- Fibers: Causes issues like poor yarn twisting, thread tangling, and thread breakage.

- Film/Foil: Problems include dust adhesion due to static, film sticking to rollers, and pinhole formation caused by electrostatic discharge (ESD).

Medical Industry:

- Clothing/Garments: Charged clothing poses a risk of igniting oxygen, anesthetic gases, and other flammable gases.

- Packaging Materials: Static charge attracts dust and debris, increasing the risk of foreign object contamination during packaging.

Other Industries:

- Powder Materials: Risks include static-induced clumping, scattering, poor screening/sifting, and dust explosions triggered by electrostatic discharge.

- Pipes/Ducts (Transportation): Causes dust adhesion, fires due to ESD, and electric shocks.

- Paper: Leads to printing defects (ink splatter, etc.), paper sticking together, and ink transfer to the back side of other sheets after printing.

ESD varied impacts—ranging from yield loss and product defects to serious safety threats—demonstrate the pervasive danger of uncontrolled static electricity. Implementing a comprehensive ESD control program is therefore essential for protecting products, ensuring quality, and safeguarding personnel in all affected sectors.