O que é um sistema de torniquete ESD?

Um sistema de torniquete ESD integra a deteção de descargas electrostáticas (ESD) com o controlo de acesso. Garante que o pessoal está devidamente ligado à terra antes de entrar em áreas sensíveis, como zonas de fabrico de produtos electrónicos, para evitar danos estáticos.

Como funciona o sistema de torniquetes ESD?

A completada Sistema de torniquete ESD inclui Verificador de ligação à terra do pessoal, torniquete, dispositivos de controlo de acessoe software de gestão. Os utilizadores autenticam-se através de controlo de acessoo sistema testa a integridade da ligação à terra (pulso/calçado) em relação às normas (por exemplo, <35 megohms). Se for aprovado, o torniquete é desbloqueado; os testes falhados accionam alertas. Entretanto, o software regista os dados de conformidade para auditorias, assegurando que as zonas sensíveis à estática permanecem protegidas.

Visão geral do fluxo de trabalho

- Autenticação: Os utilizadores verificam a identidade através de RFID, biometria, código QR, código de barras ou outros métodos.

- Ensaios ESD: O sistema verifica a resistência de ligação à terra das correias de pulso e/ou do calçado.

- Decisão de acesso:

- Passar: O torniquete abre-se para a entrada.

- Falhar: Acesso negado; alerta para uma ação corretiva imediata.

- Registo de dados: Todos os testes e eventos de acesso são registados para efeitos de auditoria de conformidade.

Detalhes do componente

1. Testador de ligação à terra do pessoal

- Função: Mede a resistência eléctrica das correias de pulso e do calçado ESD (por exemplo, sapatos, ligadores de terra para o calcanhar/dedos) para garantir uma ligação à terra adequada (normalmente <35 megohms de acordo com ANSI/ESD S20.20).

- Conceção:

- Placas de teste duplas para controlos simultâneos da correia de pulso e do calçado.

- Indicadores visuais/auditivos (por exemplo, LEDs, alarmes) para o estado de aprovação/reprovação.

- Conformidade: Valida a adesão ao ANSI/ESD S20.20 e IEC 61340-5-1 para a ligação à terra do pessoal.

2. Portão de torniquete

- Mecanismo: Uma barreira física (por exemplo, abas ópticas abertas ou retrácteis, braços mecânicos rotativos) que só se desbloqueia após um ensaio ESD bem sucedido.

- Material: Aço inoxidável 304/316, resistente à ferrugem e à corrosão e condutor para evitar a acumulação de eletricidade estática.

- Direção: Normalmente unidirecional para assegurar uma entrada/saída ordenada.

3. Dispositivo de controlo de acesso

- Leitor RFID: Verifica os crachás dos empregados para verificação da identidade.

- Sensores biométricos: Reconhecimento facial ou scanners de impressões digitais para uma autenticação segura.

- Integração: Liga os resultados dos testes ESD às permissões de acesso em tempo real.

4. Software de gestão ESD

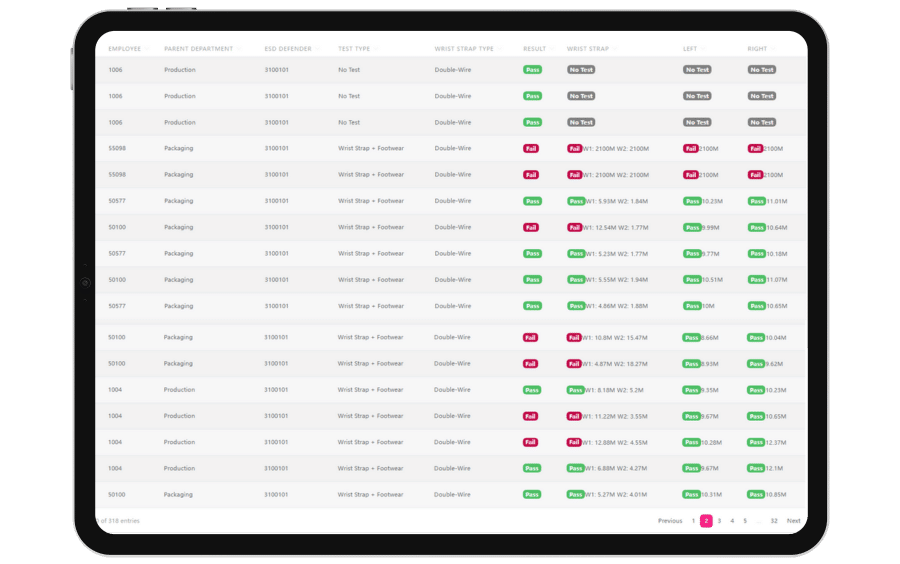

- Recolha de dados: Regista os resultados dos testes (aprovação/reprovação), carimbos de data/hora, IDs de utilizador e valores de resistência de ligação à terra.

- Relatórios de conformidade: Gera registos prontos para auditoria para cumprir os requisitos ANSI/ESD S20.20 e IEC 61340-5-1 para dados de verificação retidos.

- Alertas e análises: Envia notificações de testes falhados e análise de tendências (por exemplo, falhas frequentes de utilizadores específicos).

Como instalar um sistema de torniquete ESD?

Instalação de um torniquete ESD num zona ESD sensível suscita frequentemente preocupações: O processo é complicado? Exigirá conhecimentos especializados? Quanto tempo de inatividade devemos esperar? A boa notícia é que Os torniquetes ESD Defender foram concebidos para uma utilização sem problemas. Mais de 90% de cablagem e pré-configuração são concluídos antes do envio, permitindo uma instalação simplificada no local que até os não especialistas podem realizar.

1. Preparação do local

- Marcações: Utilize um lápis para delinear a posição da base do torniquete e os caminhos de encaminhamento dos cabos. Assegurar a conformidade com os requisitos da zona ESD da instalação.

2. Trabalho de base e passagem de cabos

- Perfurar e encaminhar:

- Cortar canais para os cabos (separar alta tensão e baixa tensão linhas em condutas dedicadas).

- Alternativa: Utilizar um Base do torniquete (pré-fabricado) para evitar danos no pavimento. A base fixa o torniquete e oculta os cabos de forma organizada.

3. Montar o torniquete

- Colocar o torniquete no local marcado.

- Fixe-o utilizando parafusos de expansão (incluído). Assegurar o alinhamento vertical com uma ferramenta de nivelamento.

4. Instalar o verificador de ligação à terra

- Fixar o Testador de ligação à terra para pessoal ESD para o torniquete (ranhuras pré-perfuradas).

- Ligue a cablagem do aparelho de teste ao torniquete de acordo com as instruções fornecidas diagrama do circuito (corresponder aos códigos de cores).

5. Ligar e testar

- Energizar o sistema. Verificar:

- Resposta de rotação do torniquete.

- Funcionalidade do testador (por exemplo, alertas LED para verificações ESD falhadas).

Feito!

Para resolução de problemas ou configurações avançadas, contactar Suporte do ESD Defender em esd@macrosafegates.com.

Quanto tempo é que um torniquete demora a rodar?

Como um dos dispositivos de controlo de acesso mais comuns, Viragens ESDtile Normalmente, demora cerca de 2 segundos a completar uma rotação completa, garantindo uma passagem eficiente e segura para os indivíduos.

Quais são as vantagens de utilizar um torniquete ESD numa instalação de fabrico?

Tal como referido no nosso artigo anterior, Porque é que o controlo ESD é crucial para o fabrico de produtos electrónicos? a eletricidade estática não controlada representa um risco grave para Dispositivos ESDsO que leva a defeitos nos produtos, tempo de inatividade operacional e perdas financeiras. Partindo desta base, este artigo explora a forma como a integração de Torniquetes ESD nas instalações de fabrico reforça os programas de proteção ESD, ao mesmo tempo que proporciona benefícios operacionais mensuráveis.

1. Conformidade forçada com os protocolos ESD

Os torniquetes ESD funcionam como um ponto de controlo, assegurando que o pessoal só entra em áreas controladas depois de se ter ligado devidamente à terra através de calçado ESD, braçadeiras ESD ou outro equipamento dissipativo. Ao negar a entrada a indivíduos sem a proteção adequada, estes sistemas minimizam o erro humano - uma das principais causas de incidentes com ESD - e reforçam uma cultura de responsabilidade.

2. Integração perfeita com os sistemas de pavimento e de ligação à terra ESD

Os torniquetes ESD modernos são concebidos para funcionar em sinergia com Pavimento ESD e infraestrutura de ligação à terra. À medida que o pessoal passa, os pontos de contacto do torniquete verificam a conetividade eléctrica contínua entre o seu calçado ESD e o chão. Esta monitorização em tempo real evita a acumulação acidental de estática antes de os trabalhadores acederem a zonas de alto risco.

3. Prevenção do acesso não autorizado

Para além da conformidade com ESD, estes torniquetes aumentam a segurança das instalações. Ao restringir a entrada a pessoal autorizado - através de crachás RFID, biometria ou códigos PIN - impedem que funcionários ou visitantes sem formação entrem inadvertidamente em áreas sensíveis a ESD, reduzindo os riscos de contaminação e manuseamento incorreto.

4. Informações baseadas em dados para a melhoria dos processos

Os torniquetes ESD avançados registam as tentativas de entrada, as taxas de conformidade e os dados de verificação da ligação à terra. Estas informações ajudam a identificar problemas recorrentes (por exemplo, correias de pulso defeituosas, lacunas de formação) e apoiam auditorias para normas da indústria como ANSI/ESD S20.20 ou IEC 61340-5-1.

5. Controlo da contaminação

Muitos torniquetes ESD incorporam chuveiros de ar ou tapetes pegajosos para remover contaminantes particulados do calçado e do vestuário. Esta dupla funcionalidade protege tanto contra descargas estáticas como contra defeitos relacionados com poeiras em ambientes de salas limpas.

6. Eficiência de custos e escalabilidade

Embora o investimento inicial seja mensurável, os torniquetes ESD reduzem os custos a longo prazo ao evitarem o retrabalho relacionado com ESD, reclamações de garantia e danos no equipamento. Os designs modulares permitem a escalabilidade, adaptando-se a expansões de instalações ou fluxos de trabalho em evolução

Os torniquetes ESD não são meros dispositivos de controlo de acesso - são ferramentas estratégicas que preenchem a lacuna entre os protocolos ESD teóricos e a conformidade no mundo real. Ao automatizar as verificações, aplicar normas e fornecer dados acionáveis, transformam o controlo estático de uma obrigação reactiva num ativo proactivo.